No products in the cart.

Protect the investment you have made in surgical instruments and improve the outcomes of your surgeries by regularly inspecting your surgical scissors. Regular inspections ensure that your surgical scissors are in optimal working condition, allowing you to promptly identify and address common issues like dullness, misalignment, or damage. Inspections also help mitigate risks associated with the use of defective or damaged surgical scissors and promotes surgical safety, reducing the likelihood of adverse outcomes. By addressing minor issues early on and following regular cleaning, sterilization, and storage protocols, you can extend the usable lifespan of your surgical instruments, reducing the need for frequent replacements and the associated costs.

Well-maintained surgical scissors contribute to efficient surgical procedures by enabling smooth, precise cuts. Sharp, properly aligned scissors minimize tissue trauma, reduce operative time, and improve post-op recovery time, benefiting both surgical teams and patients.

Inspect your surgical scissors before each use, after each use, and after sterilization to ensure they remain in optimal condition. Before every surgical procedure, inspect your sterilized instruments to visually confirm they are clean, sharp, and in proper working order. This pre-use inspection helps identify any issues that could affect their performance during surgery. After using them, verify that they have not been damage, contaminated, or subjected to undo wear and tear. This post-use inspection is vital for identifying issues that may have arisen during the procedure and ensures they are properly cleaned and sterilized for the next use. Sterilize surgical instruments after use. Once again, inspect them after sterilization to ensures that they are properly positioned and free from debris. You also need to confirm that they were not damaged by the sterilization process. Implementing a regular maintenance schedule for surgical instruments is essential for ensuring their longevity and performance.

When you purchase new surgical scissors, you should inspect them to verify their quality, sharpness, and functionality. Identify any manufacturing defects or issues that need to be addressed before using them in surgical procedures.

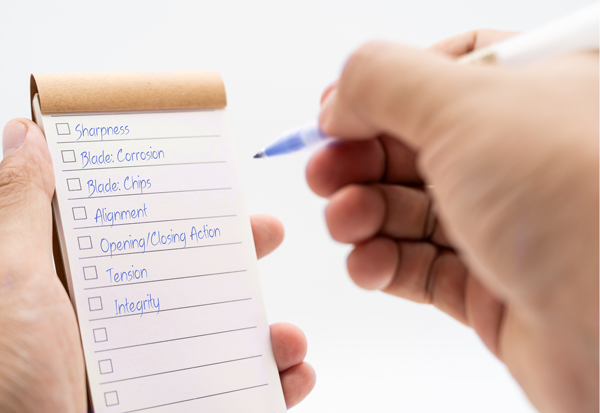

Here are some tips for checking your surgical scissors.

Check for Sharpness

Test the blades for sharpness first. Ensure that the blades can cut smoothly without snagging or tearing tissues. You can test this by cutting through a thin piece of surgical gauze or fabric. Do NOT cut paper, which can dull your blades.

Inspect the Blades

Examine the blades. Look for any signs of corrosion, pitting, or discoloration on the blades. These can indicate damage or poor maintenance. Look for nicks or burrs along the blade’s edge. The blade’s edge should be smooth to touch. Be careful if you run your finger along the edge. A sharp blade will cut.

Check for any cracks, chips, or malformations in the blades. High quality surgical steel and titanium scissors should last for many autoclave cycles, though student grade or disposable scissors may not hold up to the temperature fluctuations of repeated autoclaving.

TIP: A pair of SuperCut scissors will have one blade honed razor sharp. The other blade will have micro-serrations along the edge. You will be able to feel those serrations. Do not try to sharpen a micro-serrated blade. By design, they will last longer and maintain their edge better than standard blades. The serrated blade will grip the tissue while the sharp blade sheers it cleanly.

Evaluate the Alignment

The blades should meet evenly along their entire length when held in the closed position. Hold the blades up to the light and check for any gaps or overlaps between the blades. Gaps can affect the precision of your cuts. When the blades touch along the entire length of the blade from tip to pivot point, you get a smooth uniform cut. Gaps result in incomplete cuts or leave tissue remnants, whereas overlaps can pinch or tear the tissue.

Test the Opening and Closing Mechanism

Open and close the scissors repeatedly to ensure smooth and effortless movement. There should be no sticking, binding, or resistance during operation. You may feel a subtle feedback sensation in the handles as the scissors open and close. You shouldn’t feel or hear any squeaking or grinding. With a fine pair of Vannas or spring scissors, you should feel a consistent, gentle resistance as you compress the handles to close the scissors, and they should open smoothly as you release the pressure on the handles.

Assess the Tension

The tension between the blades should be just right—not too loose that they don’t cut effectively, and not too tight that they’re difficult to open and close. This tension should be well balanced throughout the range of motion.

Inspect the Handles

Like the blades, the handles should not have any cracks, breaks, or rough edges. They should provide a comfortable and secure grip.

Verify the Instrument’s Integrity

Examine the entire length of the scissors for any bends, twists, or deformities that could compromise their structural integrity.

Regular inspections of surgical scissors are essential for maintaining their quality, performance, and safety, ultimately contributing to positive surgical outcomes. By inspecting your surgical instruments regularly, you can ensure that they remain in optimal working condition for use in surgical procedures, promoting patient safety and surgical precision.

Add comment